|

Call Today 800-627-1033 |

|

|

|

|

||

|

|

||

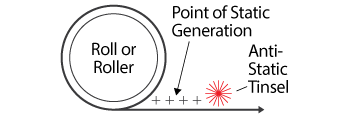

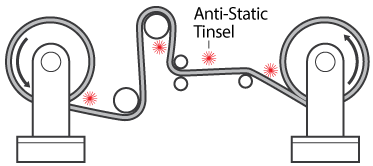

Anti-Static Copper Tinsel is a high quality, all-copper solution for reducing unwanted static build up in paper, film and foil converting operations.

The anti-static copper tinsel strands are flexible and soft to prevent scratching or other damage to products. This tinsel is effective when used on moving webs and conveyors, eliminating both negative and positive charges from static laden product. Tinsel resists breakage, matting and shedding. It is a self-energizing, induction type (no power needed) static eliminator which does not spark or cause sparks, and can be used in hazardous conditions.

Box includes two rolls at 36 feet each for a total of 72 feet.

The core is made of multiple copper wires (not string) to ensure positive grounding and strength. The fine, sharply pointed copper strands provide greater static elimination. The conductive strands are interspersed to maximize effectiveness, but are not so dense as to make it easy to collect dust and dirt particles.

| Material | 100% copper strands |

| Core composition | Multiple copper wires (not strings) ensures positive grounding and strength. |

| Outer diameter | 1.25" (32 millimeters) |

| Maximum length | 72' roll, 36 ft (12 meters), each box consists of (2) 36' rolls |

![]()

Home | Request a Quote | Product Index | Online Catalog |

Barrels & Screws | Electrical Products | Hoses & Fittings |

Molding Accessories | SDS Sheets | Credit Application | Terms & Conditions | About Us | Contact Us

7925 N. Clinton St., Fort Wayne, IN 46825-3113, USA

E-mail: Sales@ServicesForPlastics.com

Contact Webmaster regarding content or link problems

Copyright 1997-2026 | Services For Plastics, Inc. | All rights reserved. | Privacy Policy