|

Call Today 800-627-1033 |

|

|

|

|

||

|

|

||

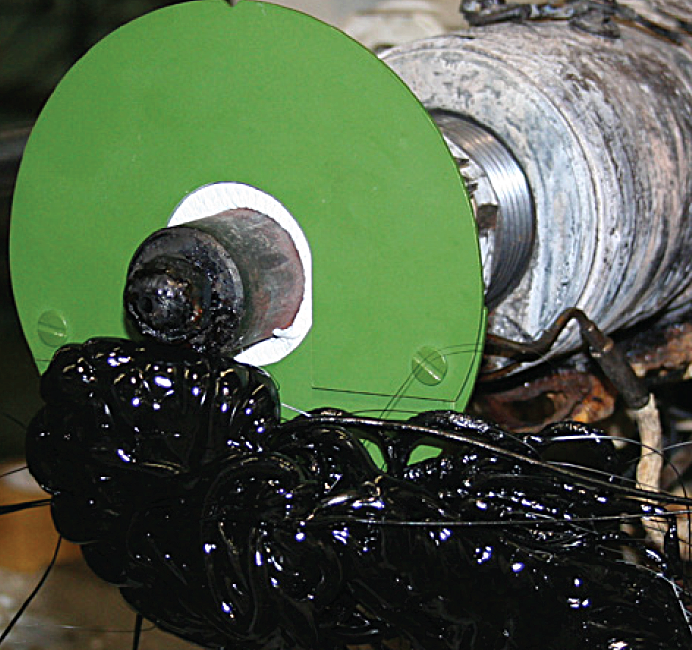

DroolShieldŽ fits on the nozzle of an injection machine and protects drool-back from destroying heater bands, wiring, and insulation blankets. The Teflon coating on the exterior makes for easy removal of plastic drool. DroolShieldŽ is adjustable to fit any machine, install within seconds, and because they can withstand temperatures up to 700°, they provide a reusable, long-term solution.

Q: What is drool?

A: Plastic injection molding machines will sometimes leak residual molten plastic from the barrel end after the mold is opened. This residual, sometimes in sizeable quantities, is known as drool.

Q: What is a DroolShieldŽ?

A: DroolShieldŽ is a cost-effective device which, when positioned over the end of the nozzle of an injection molding press, deflects damaging drool away from key press components.

Q: What kind of damage does DroolshieldŽ prevent

A: By deflecting drool away from wiring, any thermal blankets and heater bands, the risk of damage to those components is eliminated. Replacing damaged heater bands alone can be costly and time-consuming. Save time and money, purchase SFP DroolShieldŽ today!

Q: How difficult is installation?

A: Installation of DroolShieldŽ is not difficult at all. Simply slide the DroolShieldŽ over the nozzle end and secure in place. Installation takes just seconds with no equipment downtime or modifications. It's an easy way to save both time and money. See diagram for information on installation here.

Q: How effective is DroolshieldŽ at high temperatures?

A: The modified closed-cell copolymer construction of every DroolShieldŽ affords excellent heat resistance at temperatures up to 700° F.

Q: Does DroolShieldŽ have to be sized for each press in my operation?

A: DroolShieldŽ is adjustable to fit any machine. New perforated slots allow for greater flexibility.

Q: What is the economic benefit of using DroolshieldŽ?

A: When unwanted drool escapes, the damage caused to heater bands and other key components, as well as resulting downtime from that damage, can be costly. By eliminating that risk of damage, DroolShieldŽ saves operation dollars and invaluable time.

![]()

Home | Request a Quote | Product Index | Online Catalog |

Barrels & Screws | Electrical Products | Hoses & Fittings |

Molding Accessories | SDS Sheets | Credit Application | Terms & Conditions | About Us | Contact Us

7925 N. Clinton St., Fort Wayne, IN 46825-3113, USA

E-mail: Sales@ServicesForPlastics.com

Contact Webmaster regarding content or link problems

Copyright 1997-2026 | Services For Plastics, Inc. | All rights reserved. | Privacy Policy